If you own or manage a fleet of equipment, you must know how to effectively look after your equipment, and maintenance is a key aspect of that care. Beyond your equipment, attachments can become damaged and worn down over time, so taking care of them is just as important for maintaining productivity and completing projects successfully.

As different attachments perform different functions, you’ll likely need to take varying approaches to attachment maintenance. Learn about why work tool maintenance matters, the most common parts of attachments that need maintenance, and how to care for and repair your parts below.

Jump to Sections:

- The Importance of Regular and Preventive Maintenance

- Common Types of Attachments Requiring Maintenance

- 6 Types of Attachment Parts That Experience the Most Wear

- 5 Essential Work Tool Maintenance Tips

- How to Choose the Right Attachments

The Importance of Regular and Preventive Maintenance

Extending your equipment maintenance plan to include attachments has many benefits. After all, functioning equipment can only go so far — your attachments must also work properly to get the most out of them. In particular, preventive maintenance can help you keep problems from happening instead of treating them once they’ve already occurred.

Some of the reasons why implementing preventive maintenance is so essential include:

- Extended life span: If you can prevent attachments from breaking down, taking on wear and tear and undergoing multiple mechanical repairs, they’re much likelier to last for their expected life spans.

- Reduced repair costs: Because preventive maintenance prevents issues from occurring, you can experience fewer repair and replacement expenses.

- Less downtime: Any kind of downtime has an impact on the business, but unexpected downtime, in particular, can result in significant financial loss. With no plan to address the downtime, you have to scramble to get your fleet back in working order. With preventive maintenance, downtime is less likely.

- Enhanced performance: If you don’t maintain your attachments, they might function slowly or not complete their functions effectively. Keep your attachments in proper working order with preventive maintenance.

Common Types of Attachments Requiring Maintenance

There are many popular attachments on the market, each requiring different kinds of maintenance based on their performance and functions.

- Augers: If you want to practice proper skid steer attachment maintenance, you should start with the augers. An auger attaches to a skid steer loader to drill holes into the ground. If you don’t maintain this attachment correctly, you might struggle to drill straight holes into hard ground. The flighting and gearbox are two components that require inspection and maintenance.

- Brooms: Brooms are versatile, as they fit onto skid steer, compact track loaders and wheel loaders. They sweep to collect dirt and dust. Properly looking after your brooms, such as inspecting the mounting hardware, allows them to function optimally by clearing debris.

- Blades: Blades commonly attach to bulldozers to push material. Improper maintenance of this attachment type could reduce its strength and effectiveness. Keeping the blade sharp and free of cracks and bends is essential.

- Buckets: A crucial part of excavator attachment maintenance is looking after your buckets. These attachments enable your equipment to dig and scoop large materials. If you don’t look after your buckets, they could crack, leak and wear on the edges, reducing their performance.

- Brushcutters: Brushcutters help clear larger land and growth areas. Maintaining them ensures they’re sharp enough to remove brush effectively.

- Forestry mulchers: Mulchers are practical attachments that clear vegetation. Like brushcutters, these require upkeep to ensure they’re effective and safe for use.

- Grapples: Grapples allow operators to easily move bulky materials. They require maintenance to ensure they can effectively hold large, heavy objects without dropping them. If the clamping mechanism or hydraulic cylinders are worn or damaged, they can’t perform properly.

- Hammers: Hammers are another versatile attachment type, as you can use them with multiple types of equipment. Some compatible options include skid steer loaders, excavators and backhoes. These attachments require maintenance to ensure they’re in proper condition to break rocks and other hard materials effectively.

- Rakes: Construction companies often use Harley or landscaping rakes to break up ground so it’s even and ready for landscaping. Rakes need to function correctly to churn soil so rocks come loose. Damaged tines or insecure mounting hardware can impact performance.

- Trenchers: As their name suggests, trenchers create trenches, digging into the ground with tremendous power. If you don’t maintain your trencher’s chain, teeth and hydraulic system, it might lose some of this strength, and creating trenches will take longer and put more strain on it.

- Stump grinders: You can mount stump grinder attachments to multiple equipment types. Once you attach a stump grinder to a loader or an excavator, you can easily remove stumps and clear an area for construction. Stump grinders use incredibly sharp teeth to remove stumps, and keeping these teeth sharp requires some upkeep.

- Tillers: Tillers help prepare the ground for various landscaping and construction tasks. With a tiller attachment, you can effectively break up hard, compacted ground into looser earth more suited to planting. On an industrial scale, tillers need to till large amounts of ground quickly, so you must service them to keep them functioning smoothly with maintained tines and lubricated gearboxes.

6 Types of Attachment Parts That Experience the Most Wear

If you rely heavily on your attachments to complete your daily tasks, a malfunctioning part can have a significant impact on your operations. It’s important to have a maintenance plan for all your attachments, even those you don’t use as often. However, a few parts of many construction attachments undergo more wear and tear than others.

1. Cutting Teeth

Cutting teeth are sharp parts of an attachment that make it easy for operators to dig, saw and cut. Some attachment types that commonly use cutting teeth include:

- Mulchers

- Trenchers

- Harley rakes

- Stump grinders

These teeth require maintenance to stay sharp. Otherwise, they’ll grow dull and perform less effectively. Even with proper maintenance, cutting teeth eventually lose their edge, at which point you should replace them.

2. Cutting Blades

Teeth aren’t the only way attachments can cut through materials — many attachments use cutting blades. Augers, tillers and brush cutters all make use of blades to cut through various materials. Dull blades take much longer to cut than sharp ones, so you should add blade sharpening to your maintenance schedule if you have this attachment.

3. Ground Engaging Tools

Ground engaging tools (GET) refer to the parts of your attachment that make contact with the ground and perform duties like cutting and moving. Many attachment types fall under this category since having GET makes it easy to remove a part when you don’t need it, you want to do maintenance, or you need to swap it for another type of attachment. Equipment types that often use GET include cutting and blade edges, bucket teeth and wear protectors.

While the primary function of GET is to improve performance, they also play a secondary role by protecting certain parts of your equipment and attachments, like your buckets and blades. Because these tools perform such specific and repetitive duties, you may start to notice certain wear patterns. Take note of these and address issues before they can affect performance.

4. Hydraulic Systems

Hydraulic systems usually consist of pumps, lines, fluids and connectors. Hydraulics use liquid pressure to perform certain functions, and many equipment types use this type of operation. These systems often require more in-depth maintenance than other parts of attachments because of how many parts they have.

How you approach hydraulics maintenance depends on the attachment and how the system works, but a few actions you should add to your checklist are:

- Changing the hydraulic fluid.

- Checking the oil.

- Replacing the oil filters.

- Replacing seals.

5. Grease Points

Grease points, also known as grease fittings, protect the mechanical aspects of your attachments from friction and ensure they remain lubricated. However, if you don’t regularly service and maintain them, they could fail to lubricate attachment joints, leading to damage from friction. Dirt and debris can also damage them, which could reduce their capacity for efficient lubrication.

6. Bearings and Bushings

Bushings and bearings are similar in the sense that they reduce friction between moving parts. Bushings are types of bearings, but not vice versa. These cylindrical tubes act as a sleeve over attachment parts, allowing for smoother, friction-free movement.

If these parts sustain damage due to improper maintenance, the consequences could be significant. You’ll likely have to replace the bearings and bushings, but if you do so too late, your attachments may sustain damage from the friction created when the bearings and bushings stop working well.

5 Essential Work Tool Maintenance Tips

Understanding the importance of attachment maintenance is the first step. Now, you can build an effective strategy to maintain your attachment parts, keeping them effective and maximizing their life spans.

1. Develop an Attachment Maintenance Schedule

Rather than relying on yourself to remember when to schedule maintenance for which attachments, consider setting up a maintenance routine for all your parts. This way, you can prioritize maintenance amid all of your other important work tasks.

Look at how often it’s recommended to service specific parts and how frequently you use them. Then, create a routine around your findings for the best results. It’s best to include various types of maintenance on a daily and weekly basis.

Additionally, determine specific milestones during which you need to do a full service and maintenance check for equipment parts. This information is often found in the attachment’s service manual or from the equipment supplier. This part of your maintenance routine will be much more in-depth and include everything you don’t do during smaller checks. Depending on what type of attachment you have and where you got it from, you might be able to receive service support through the provider.

Make your attachment maintenance schedule known across your operator team so everyone understands their responsibilities. It’s also helpful to create a reporting system, so operators know how to report issues they spot during their daily checks.

2. Create a Maintenance Checklist

With a maintenance schedule as your foundation, you can outline specific maintenance tasks in a checklist to make sure every important aspect is covered.

- Daily: Every day, operators should visually inspect attachments for damage or wear. Beyond that, they should clean attachments as necessary, check lubrication, look for leaks and make sure all safety features are in working order.

- Weekly: On a weekly basis, have experienced operators or fleet managers assess fluid levels, tighten loose bolts, inspect parts for wear patterns and sharpness if applicable, and look at electrical components.

- Monthly: These checks involve examining components more thoroughly, so set aside specific times to temporarily take equipment out of commission when it’s not needed. Have an experienced technician assess all aspects of the equipment and its attachment, checking for corrosion, changing filters if necessary, inspecting bearings and bushings, changing fluids, and more. This is also a beneficial time to review past maintenance logs and see if any new issues have come up.

Depending on the type of equipment and attachments you have, your tasks may look slightly different — the important part is to build out a comprehensive checklist for each inspection interval.

3. Understand Seasonal Maintenance Tasks

Alongside your regular maintenance routine, taking care of specific maintenance tasks in different seasons is helpful, as weather changes can affect your equipment. Here are some considerations:

- Switch to snow tires in winter: Any equipment and attachments using tires can benefit from switching to snow tires equipped to handle the snowy terrain.

- Check for ice and frozen mud in colder months: During colder seasons, you may want to inspect the equipment to see that no ice or mud has frozen overnight, which could impact its performance.

- Look for debris in fall and spring: If you store your heavy machinery outside, you should always conduct a more thorough inspection after severe weather like storms, as debris, branches and leaves could get stuck in the equipment and cause it to malfunction. However, during seasons like spring and fall, when the weather changes rapidly, you should perform these checks more routinely.

- Prevent overheating in the summer: As you use attachments, they warm up, and already hot temperatures can cause them to get dangerously hot. Therefore, you can implement rules requiring equipment to cool off before and after use. Store equipment in shaded areas if possible, and check fluid levels regularly.

4. Keep Detailed Logs

Have a system to help you keep track of your attachment maintenance. It’s helpful to know when a part was last serviced and when it’s due for another check. It’s also useful to keep records of who performed the maintenance check and who completed any needed repairs. Keeping thorough and accurate records of any damage can help you notice trends and improve your maintenance routine.

Be sure to store your logs in a secure, accessible place so you and other team members can reference them when needed. If you use a professional service to maintain your attachments and heavy machinery, ask them for copies of their records regarding your equipment. It can also be beneficial to use both paper and digital documentation to create backups.

5. Set up Operator Training Programs

Many operators need to receive training before they use specific equipment. Operators work with attachments most of the time, so they need to know how to recognize wear and tear. You should inform all workers and managers of their maintenance duties and have precise rules in place for what to do in case there’s a problem during maintenance.

Employees should know what signs of wear and tear to look for. They must also know whether the procedure requires them to stop using the attachment until the problem is resolved. Having skilled operators who have received maintenance training increases the likelihood that you catch issues as soon as they occur. Training also equips workers with the knowledge to safely use equipment and attachments.

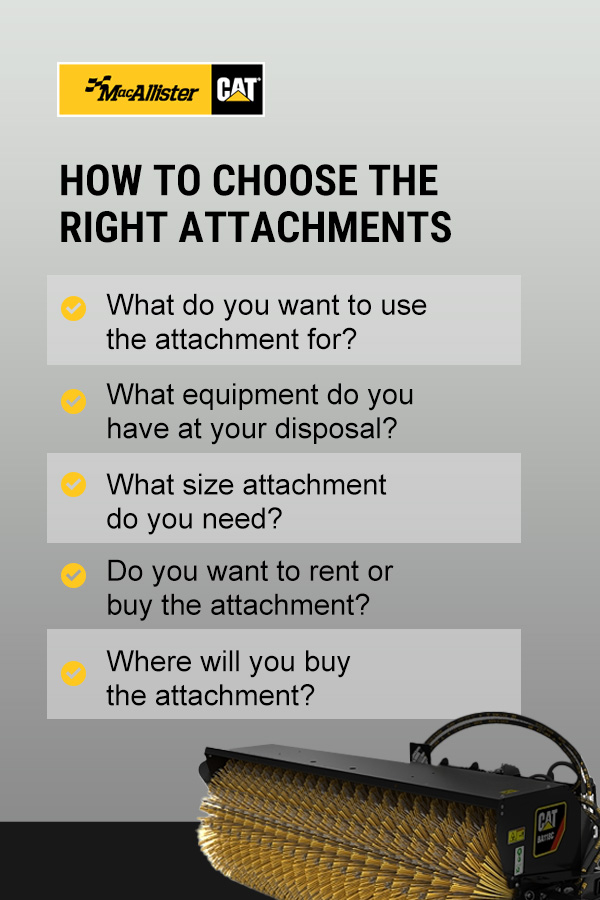

How to Choose the Right Attachments

Though maintenance plays a significant role in the effectiveness and longevity of your attachments, it’s not the only factor. Even the best maintenance won’t help much if you don’t have high-quality, reliable equipment parts. If you’re searching for new attachments to add to your fleet, ask yourself the following questions to narrow down your options:

Though maintenance plays a significant role in the effectiveness and longevity of your attachments, it’s not the only factor. Even the best maintenance won’t help much if you don’t have high-quality, reliable equipment parts. If you’re searching for new attachments to add to your fleet, ask yourself the following questions to narrow down your options:

- What do you want to use the attachment for? Because attachments perform various functions, knowing what you’re looking to accomplish with it can help you select the option that best aligns with that task.

- What equipment do you have at your disposal? Not all attachments fit on all equipment, so knowing what you own allows you to select parts compatible with your equipment.

- What size attachment do you need? Some attachments come in multiple sizes. If you perform heavy-duty work, a larger attachment may be more beneficial. It’s wise to consider your equipment, as smaller pieces of heavy machinery might not be compatible with large attachments.

- Do you want to rent or buy the attachment? In the long run, buying an attachment is more cost-effective than renting one, even though renting has lower upfront costs. While renting isn’t the best long-term commitment, it has one major benefit — you get to try the attachment before you invest in it. Renting attachments allows you to experience different attachment types to see what works best with your equipment. It’s also a suitable option if you only need the attachment for a short-term project.

- Where will you buy the attachment? The next step is to determine where you want to source your attachments from. Consider selecting a reputable supplier with enough industry experience to help you navigate the different attachments and pick the right one for your operations. You also want to choose a company that sells compatible attachments that meet industry standards. For example, if you have Cat® equipment, choose a provider specializing in Cat attachments.

About MacAllister Machinery

MacAllister Machinery is a leading heavy equipment provider in Indiana and Michigan, making us the chosen partner for many brands. With our experienced team and vast resources, we have what it takes to give your business the top-notch equipment and attachments it needs. Whether you’re interested in premier Cat machinery or have a different manufacturer in mind, we can assist.

Beyond our inventory, our excellent service is a point of pride, so whether you need help choosing equipment or want to purchase an attachment, we’re here to help along the way.

Contact MacAllister Machinery for Quality Equipment Attachments

If you’re ready to take the next step in sourcing quality attachments for your equipment, MacAllister Machinery has an extensive inventory of new and used equipment, plus heavy machinery for rent. Find a location near you to get started, or contact our helpful team to learn more about what we have in stock and what our experts recommend.